Laminators offers installation systems, videos

- August 26, 2020

- Posted by: Alan Hageman

- Category: News

Hatfield, Pa.-based Laminators Inc. is offering new field-fabricated installation systems and instructional videos. Exterior wall envelopes can contribute to building performance by:

- Manage moisture flow (liquid water and water vapor) through the exterior wall

- Minimize the impact of exterior air temperature on interior conditioned space

- Retain the majority of building-generated heat or conditioned air

- Control the spread of fire across the exterior

- Provide structural support for an aesthetic veneer system

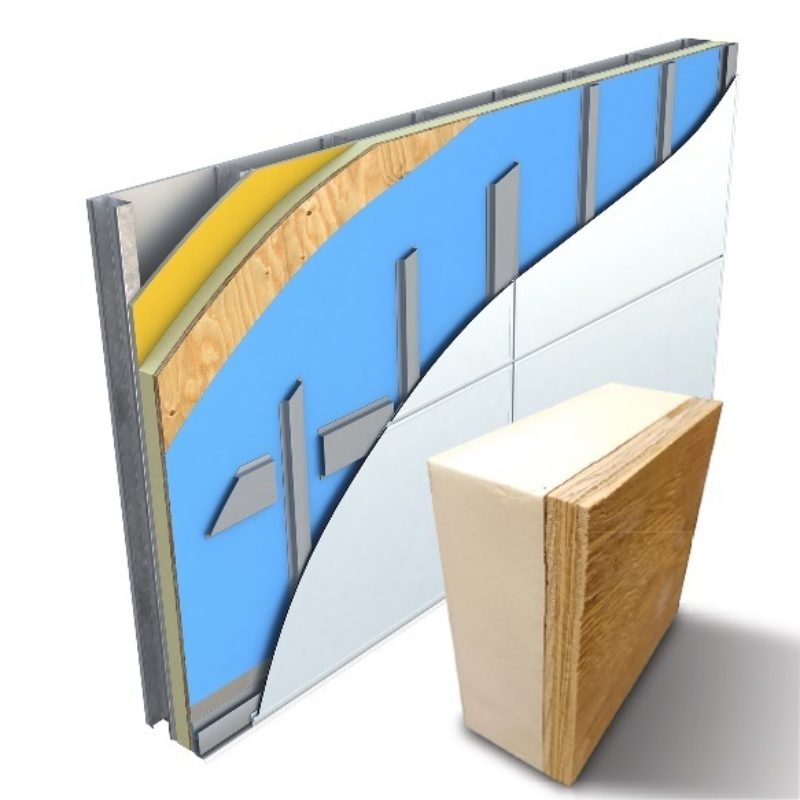

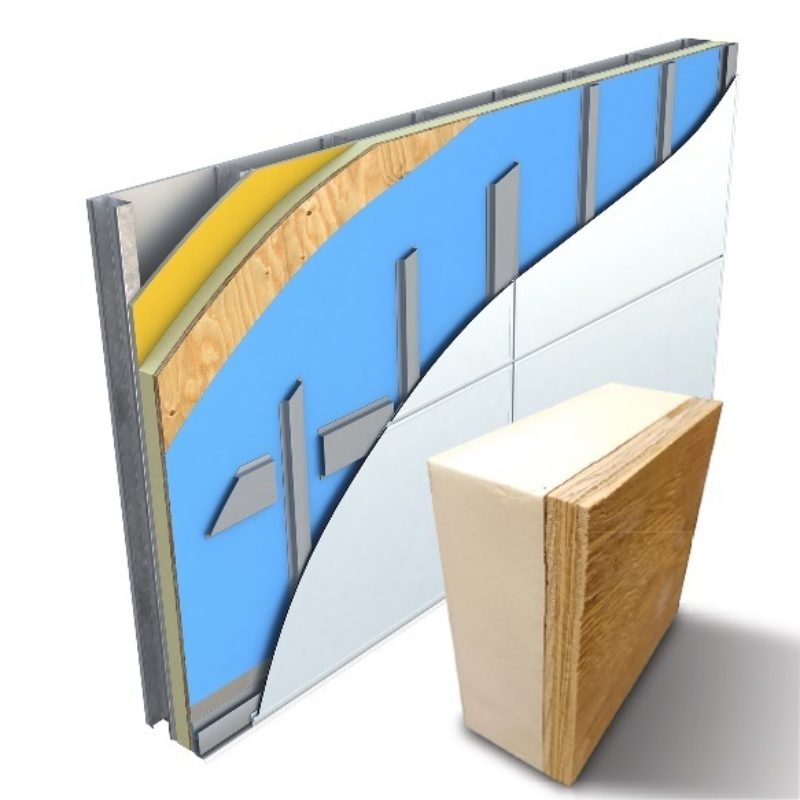

Laminators’ back-drained and ventilated, field-fabricated installation systems (one-piece, tight-fit molding; clip and caulk) use aluminum extrusions as sub-framing members to create a 7/8-inch deep cavity behind the panel veneer.

The installation systems provide:

- Additional cavity space improves air flow

- A drainage path is easily achieved through gaps in aluminum sub-framing members

- Aesthetics of Laminators’ legacy systems with improved moisture management and allowance for air exchange

The one-piece, tight-fit molding system has aluminum moldings used to encapsulate panel edges available in flat and reveal styles. The clip and caulk system provides the traditional look of a shop-fabricated wet seal system without panel fabrication. For both systems, the back-drained and ventilated sub-framing provides improved moisture management and increased ventilation.

When combined with Laminators’ Omega CI product, the installation system is a solution for veneer installations over continuous insulation while balancing thermal performance, water management and fire resistance code requirements.

To view the videos, visit Laminators YouTube channel at www.youtube.com/channel/UCE_kX32JCJnOvJfN2xueeFQ.